Thermal improvements can be made to many homes. If you want to reduce your carbon emissions and keep your energy bills low, installing insulation and draught-proofing can reduce heat loss and, therefore, your energy needs and bills.

What is spray foam loft insulation?

Spray Polyurethane Foam (SPF), hereinafter referred to as ‘spray foam’, is a form of insulation material that can be applied to roof spaces, walls and floors. It is installed by spray gun application, which can be advantageous when working with unusual designs and tight spaces where a custom application is necessary for safety or to minimise disruption.

However, there is often limited understanding among consumers regarding spray foam modification to their property and its impact on valuation, home surveys and lender decisions. Moreover, Trading Standards and various media reports highlight issues with ‘cold-calls’ or unsolicited offers to sell or remove spray foam installations. This consumer guide aims to provide clarity in these areas.

Spray foam insulation may seem like a simple way to reduce heat loss in your home, but it should be viewed as a serious modification. This consumer guide aims to inform the homeowner on the ways in which spray foam insulation could impact a property.

RICS is the largest organisation for professionals working in property, land and construction worldwide.

RICS members may be (but not exclusively) involved in all types of surveying including, defect surveys, pre-purchase building and home surveys, and the valuation process for secured lending, which is where spray foam work impacts.

Application of this consumer guide

This consumer guide applies to alterations and modifications of existing roof structures in loft voids where homeowners are considering the application of or have already had spray foam retrospectively applied to the underside of their roofs.

Spray foam changes a ‘cold roof’ into a ‘warm roof’.

This consumer guide is for use in the UK.

This consumer guide does not apply to new build structures where spray foam insulation was included when the homes were built and is original to the build-up of the roof structure and system, and loft conversions where new insulation has been designed and installed to be compatible with the conversion from loft void to a liveable room.

This guide also does not apply to roofs where a type of foam was applied to glue the roof tiles together. This is often done when an old roof is in need of replacement and the owner used spray foam as a less costly remedy to put off replacement and the primary reason was not to improve thermal performance. These roofs are often already past economic repair where the next action would be replacement.

Considering the impact on the whole property

Spray foam is an insulation material that is applied to properties to make them more thermally efficient.

However, like all insulation, its material properties, design and installation need to be considered properly before application to ensure it is suitable for your property. This is particularly important when retrospectively installing in an existing property.

Buildings are a combination of individual component parts designed to work together. Introducing new materials can have an impact, both positive and negative, on how your building performs. For example, sealing hot air inside can keep you warm but can also seal water inside and make roof repairs more difficult.

The retrofit challenge

Improving your home’s energy performance

Homeowners and tenants may want to increase insulation levels within their home to improve thermal performance and reduce energy bills. However, insulation of all kinds can also negatively impact how other parts of the building perform depending on its form, position and most importantly, the condition of the existing materials. Incorrectly installed insulation can negatively impact ventilation and result in moisture damage.

Firstly, your property needs to be wind and watertight before spending money on improving its energy performance. If a property is not maintained, it will be vulnerable to rainwater getting inside. Adding insulation to a poorly maintained roof will increase this vulnerability and accelerate the decay of any untreated timber roof structures.

Secondly, all changes need to be considered in the whole. A typical pitched roof loft void is designed to have ventilation to balance water vapour in the air, reducing the risk of condensation.

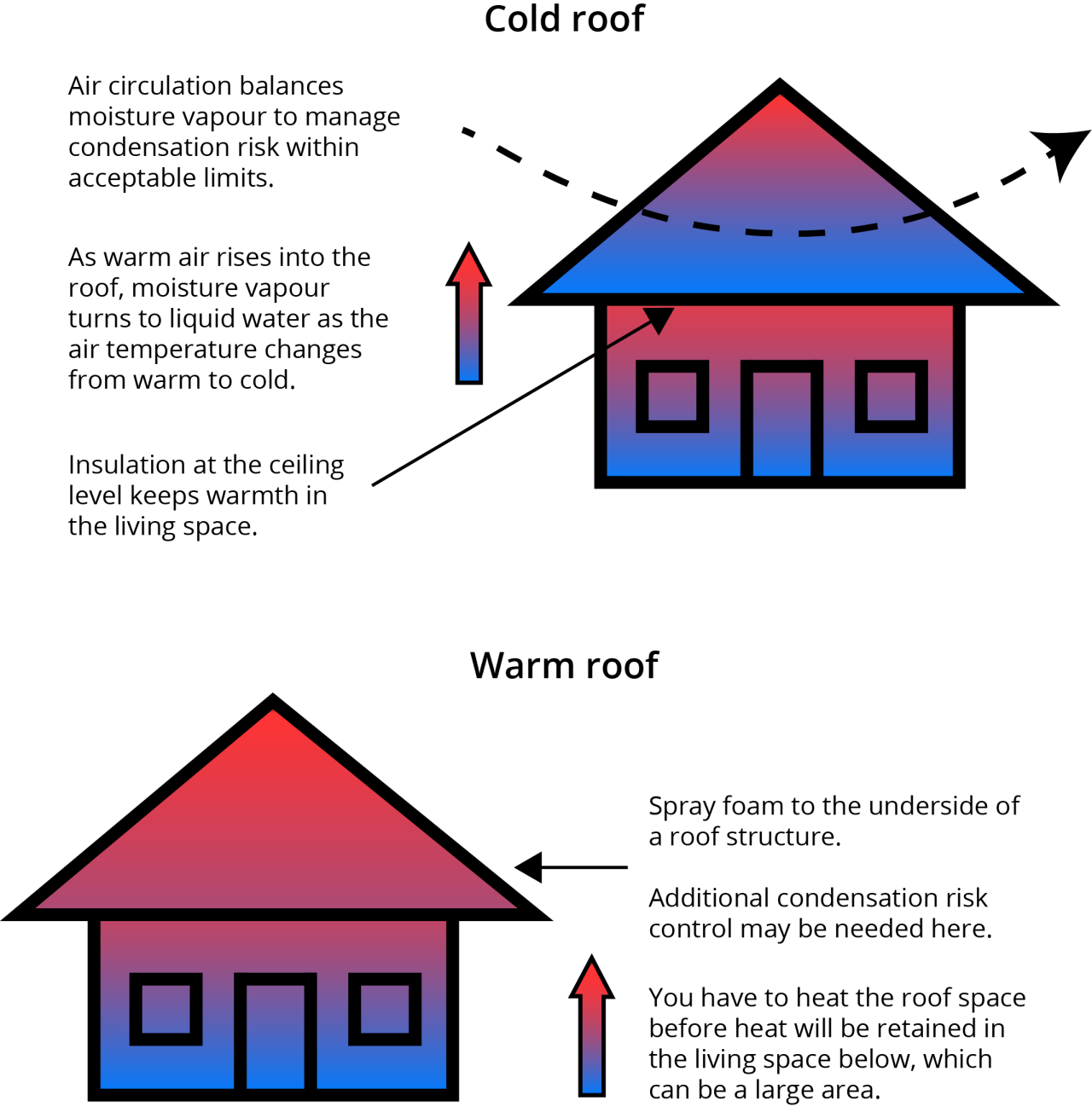

Traditional insulation is typically laid above habitable rooms at ceiling level. This is called a ‘cold roof’ because the loft becomes cold. Installing spray foam to the underside of a roof structure is called a ‘warm roof’ because the roof space becomes warm. The combination of the two insulations is a fundamental change from how the roof was originally designed to perform. Changes may lead to unexpected problems if the original design requirements are negatively impacted by the change, which can result in newly installed spray foam not meeting expectations.

What is a 'cold' and 'warm' roof?

Cold roof

- Air circulation balances moisture to manage condensation risk within acceptable limits.

- As warm air rises into the roof, moisture vapour turns to liquid water as the air temperature changes from warm to cold.

- Insulation at the ceiling level keeps warmth in the living space.

Warm roof

- Spray foam added to the underside of the roof structure.

- Additional condensation risk control may be needed here.

- You have to heat the roof space before heat will be retained in the living space below, which can be a large area.

Cold and warm roofs

Risks with spray foam insulation

There are different types of spray foam, with different performance properties, and once applied, they are not easily reversible.

RICS advises consumers to carry out appropriate checks on the material, its properties and to be aware of the risks involved by using independent experts, commercially and independently separated from the installer and manufacturer.

Hidden problems

Some spray foam insulation can make it difficult to identify problems to the roof because it restricts the view from within the roof space. If the timber roof structure is covered with spray foam it cannot be fully seen or inspected.

Climate change science indicates more frequent extreme weather events will occur, such as multiple severe storms, one after another. Storms can damage roofs and the presence of spray foam can, in certain circumstances, make repair more difficult.

If there’s a roof leak behind some types of spray foam insulation, you may not notice it. An undetected roof leak can lead to rotting timber.

It is important to look after your roof, be proactive: regularly inspect, maintain it and keep it watertight. If you already have spray foam installed in your roof you may not see a problem developing until it is too late.

Damp and condensation

As with all types of insulation, poor installation can lead to unintended and adverse consequences. Incorrectly installed insulation can lead to dampness, such as uncontrolled condensation and damage to parts of the property.

Energy saving

There is a risk that energy saving claims are not achieved if installations are not planned correctly. Spray foam insulation is a better thermal insulator than the same thickness of standard mineral wool loft insulation, however, existing loft mineral wool insulation can be topped up to modern standards of current building regulations resulting in better thermal performance than the typical maximum of 100mm of spray foam installed between the sloping roof timbers (rafters).

Topping up the existing mineral wool insulation is likely to be substantially cheaper than installing spray foam, however, takes up more loft space.

Before introducing spray foam, thermal calculations and condensation risk checks need to be undertaken by a qualified professional who has surveyed all parts of the roof. This documentation should be kept by the homeowner for future reference. Some calculations may show that the mineral wool insulation above the ceiling needs to be removed, i.e. you may not be able to have both ceiling and roof level insulation.

Removing existing insulation from above the ceiling and changing the position of the insulation may make you use more energy compared to a property well-insulated at ceiling level (because you have to heat the roof space before heat will be retained in the living space below). With some roof spaces being relatively large, e.g. in a bungalow, this may not be cost effective.

Fire safety

Polyurethane spray foam is a combustible material. Building materials are tested using British European Standard BS EN 13501-1 with typical polyurethane rating as Class E – Combustible, which ‘will only resist a small flame for a few seconds’.

You should be aware of the increasing risk to your property when using polyurethane spray foam as insulation. While uninhabited loft spaces do not require protecting from fire, in the event of a fire in your home, spray foam is combustible and will increase the likelihood and extent of damage to your property and any adjoining properties.

Damp and condensation

As with all types of insulation, poor installation can lead to unintended and adverse consequences. Incorrectly installed insulation can lead to dampness, such as uncontrolled condensation and damage to parts of the property.

There is no ‘one size fits all’ guidance for installation. Reputable spray foam manufacturers will each have their own technical literature and installation guides. Consumers must satisfy themselves that the products are installed correctly by recognised industry qualified operatives.

Consider the following matters before spray foam is installed at your property:

- Is your roof reaching the point when it will soon need to be replaced? If so, spray foam will not be cost effective.

- Is the roof free from defects and damp?

- How is ventilation to the roof structure to be controlled, as required by the manufacturer?

- Will existing insulation need to be removed to control condensation risk?

- Will the spray foam applied require additional materials such as vapour control layers?

RICS advises homeowners to seek independent expertise, commercially separated from the installer and manufacturer, to advise if spray foam is appropriate for their property. See the section Installing spray foam insulation in your home for more detail.

Most pitched roofs on houses and bungalows are designed to be ventilated and spray foam is a change to the original design.

A draughty loft above ceiling-level insulation is generally a dry loft. Air circulation balances moisture vapour to manage condensation risk within acceptable limits. Spray foam creates a warm roof void. It seals the gaps to prevent draughts and retain heat but will also seal in moisture unless adequate precautions are taken. Seek professional advice on how to manage any moisture risks.

Further installation considerations:

- Most insulation products should not be applied directly to the back of tiles/slates or be applied to remedy leaks or damage.

- Some products must not be applied to waterproof roof underlays such as bitumen sarking felts and unventilated plastic sheets because they do not let water vapour through and therefore require ventilation to remove water vapour and condensation. These roof underlay materials go under the roof tiles and above the roof structural frame.

- Some products must not be installed against roof underlays at all and must have a dedicated ventilation channel installed behind the foam to control condensation risk.

- You will need documentation to be provided that demonstrates the system was designed and installed to manufacturer’s guidance, particularly if a warranty is provided only for the insulation material and not the installation workmanship and design.

Is spray foam suitable for your home?

Listed and protected buildings

Spray foam insulation must not be installed in a listed building or other protected building or structure without prior consent. Listed building consent must be obtained in advance of the use of all spray foam insulation products.

As spray foam is a permanent installation and its removal could potentially damage the existing structure, it is not considered reversible and is unlikely to obtain consent for installation to a listed building.

In all other properties, whether spray foam insulation is suitable depends on what you are trying to achieve.

How do you use your roof space?

There are big differences between a roof void (likely used for storage only), older/ original existing rooms-in-roofs and new/retrofit habitable loft conversions. Therefore, you must use insulation appropriately and use the right kind to meet your needs. Always consider the entire property or adjacent materials before introducing spray foam insulation. If in doubt, seek independent professional advice.

Standard roof or loft void

If you are not using your roof space as a liveable room, i.e. it is not a loft conversion, it is just a roof void (maybe with some storage space) and it does not need to be heated.

The mineral wool method of insulating your ceiling within the loft void will improve the thermal performance of your home, is considerably cheaper and also makes your home’s roof easier to maintain in comparison to if spray foam is applied. See the section Risks with spray foam insulation.

Typically, you would not use spray foam on the top of the ceiling because that would likely impact other parts of the property, such as pipes, the electric supply cables to lights and smoke alarms at ceiling level.

To summarise, look at how you use your property and insulate around where you live. For example, if your roof is not a liveable space, why install insulation on the underside of the pitch of the roof? You may get more benefit fitting insulation at ceiling level in the loft void, which is directly above where you want heat retained, and this method is relatively more cost effective.

If you desire to retain heat in the loft void, plan and design how the roof void with its typical requirement to be ventilated needs to be adapted, changed and altered to head off the risks.

Existing rooms-in-roofs

Some roofs are more complex with differing requirements, such as dormer/Dutch bungalows, where large portions of the upper floors are within the roof space and there may only be a small central roof void. With spray foam application, typically, the walls in line with the roof pitch are not retrofitted with insulation because the work is disruptive to the other rooms, however, partial thermal upgrades can lead to condensation forming in different locations. Seek professional advice to upgrade a home’s thermal performance holistically, including existing rooms-in-roofs.

Loft conversions

Loft conversions are beyond the scope of this consumer guide.

If you are undertaking a loft conversion, insulation types should be considered by your designer (surveyor or architect) to see what meets yours and your home’s needs and complies with current building regulations.

Installing spray foam insulation in your home

Research the product

RICS encourages and emphasises the importance of homeowners carefully researching insulation products, as they would with any modification to their home. Consider how improvements can be made throughout the house and not just to single parts.

If you have decided installing spray foam insulation is right for you and your home, it should be designed and applied by an approved installer trained by the manufacturer and in accordance with the manufacturer’s recommended installation method while ensuring compliance with appropriate guarantees.

If you are modifying your home, RICS encourages the use of an independent, impartial professional to advise.

Record keeping

It is essential that appropriate records and photographs are taken of your home before, during and after works are completed. For example, the condition of the roof covering and structure, provision for ventilation, moisture readings taken of the roof timbers, and atmospheric moisture conditions, and these included in the building work handover information/health and safety file. These may be required in the future to prove compliance with BBA/Kiwa certification and to assist should you decide to sell or remortgage the property.

In a domestic contract situation, the duties under the Construction (Design and Management) (CDM) Regulations 2015 should be considered by the designer – whether this is a homeowner, the appointed surveyor or architect, or the contractor. If an installer or contractor is not familiar with the requirements under the CDM Regulations, that is a warning sign that they are not a competent installer.

Will spray foam insulation affect the value of your home?

The presence of spray foam insulation is a factor that could affect a surveyor’s professional opinion of value. If a surveyor encounters spray foam insulation during their inspection, they may request an independent specialist report – the results of which could impact on their opinion.

If spray foam has been applied incorrectly, or say to a listed property without prior consent, this will be reflected in the surveyor’s valuation. The surveyor will also have to conform to the instructions and any policy provided by their lender clients.

RICS recommends making sure your installer provides you with all the relevant documentation including the installation contract, relevant calculations, works carried out to the roof, any guarantee or warranty and any independent test certificate, for example, a BBA or Kiwa certificate. If you are purchasing a property with spray foam insulation already present, ensure this documentation is available as this will assist in any queries received from the valuer, lender or legal representatives.

Dos and do nots

Before installing spray foam insulation, consider the following:

- Do not accept ‘cold-call’ or unsolicited offers relating to spray foam installations.

- Do not install spray foam insulation in a listed building or other protected building or structure without obtaining listed building consent in advance.

- Do not carry out isolated alterations without careful due diligence and planning.

- Do get advice from an independent, impartial professional if you are considering alterations or modifications at your property (someone who does not have a commercial interest in selling you their product).

- Do look after and maintain your property in good repair, keeping it wind and watertight.

- Do consider the whole property before carrying out any alterations.

- Do consider how your property is designed to perform – specifically, understand where ventilation is needed in your property.

- Do consider where you live in the building and consider installing more insulation next to your living spaces, for example, at ceiling level in the loft to keep the heat near the rooms you live in.

- Do check with your mortgage provider whether their lender policy allows the installation of such products.

- Do check with your insurance provider whether their policy allows the installation of such products with potential increased fire risk.

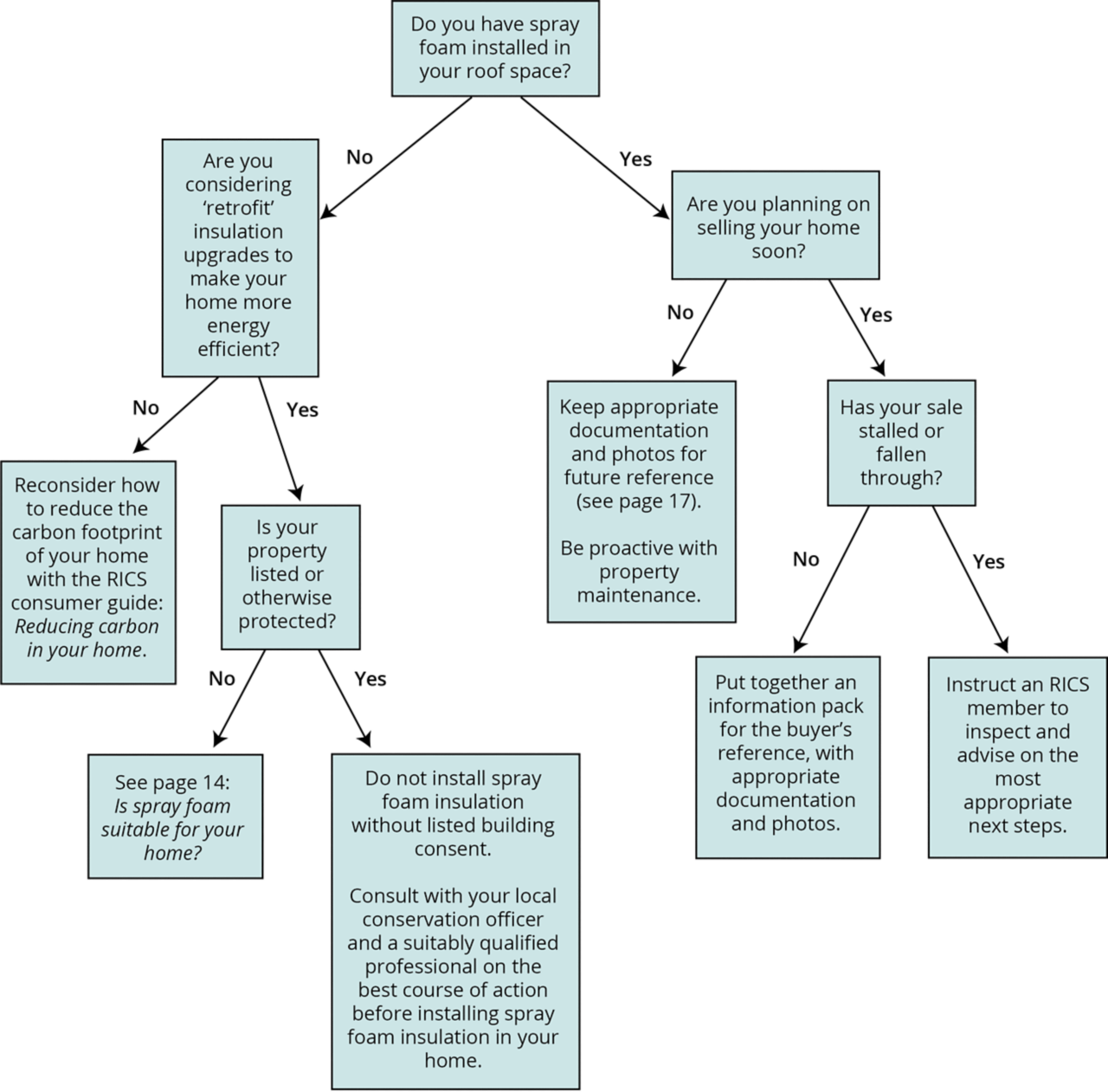

Decision tree

Use this decision tree to identify your next steps.

Consumer guides

Navigating property decisions - whether it's choosing the right survey when buying a home, resolving boundary disputes, or improving energy efficiency - can be overwhelming. RICS has created a library of free, easy-to-understand consumer guides to support confident, informed choices.